Color Management Resources

How to Read the ColorEdge Factory Report

Included in the box of every ColorEdge CG Series monitor and select CS monitors is a Factory Report which shows the measurement results of the monitor at the time of production. This page explains how each item is measured, as well as how to read the resulting values and graph information.

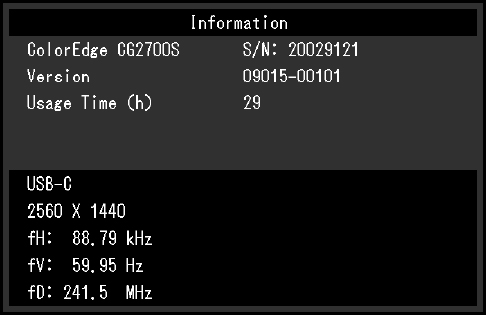

Model / Serial Number

OSD |

The product name and serial number (S/N) of the monitor that was measured is displayed at the top of the report. You can find out the serial number for your monitor by checking the product label on the back of the unit or via the monitor’s on-screen display (OSD).

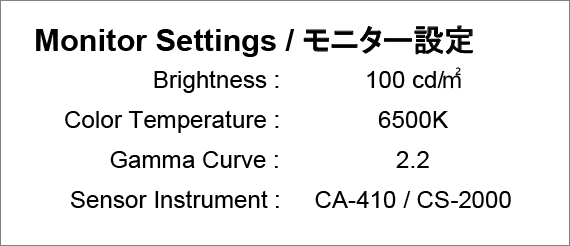

Monitor Settings

The monitor’s settings and measurement condition at the time of production are displayed as shown above. The four items described in the report are:

- Brightness

- Color Temperature

- Gamma Curve

-

Sensor Instrument

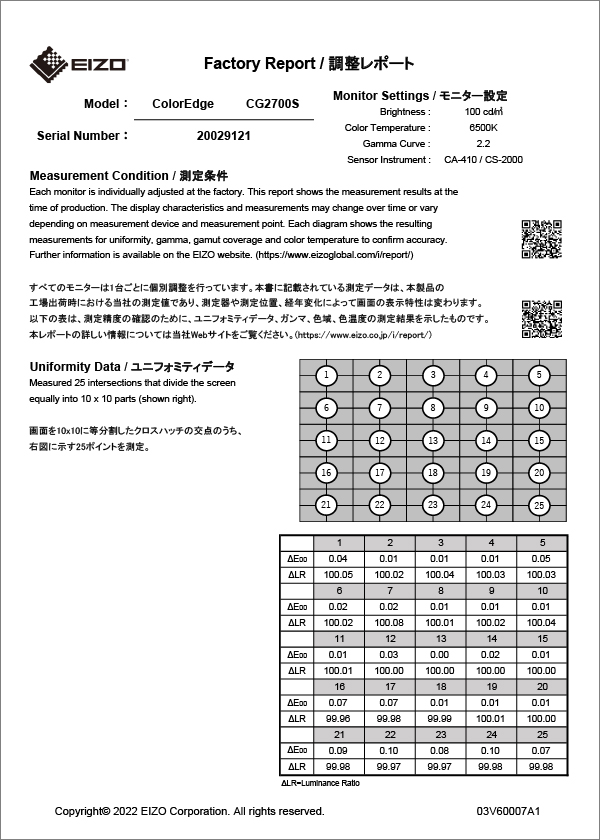

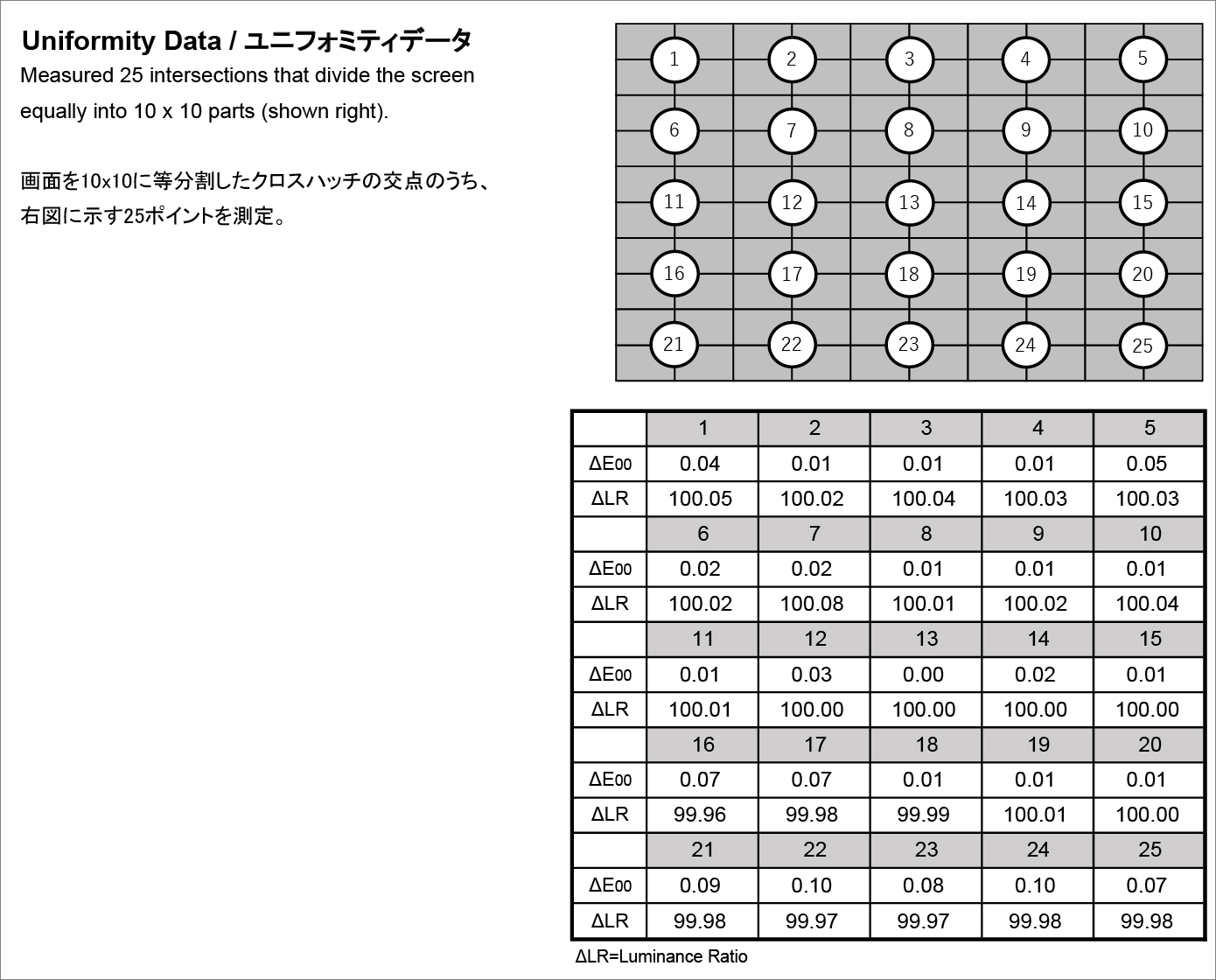

Uniformity Data

|

After measurement and adjustment, monitors are less prone to irregularities on the screen and have overall more consistent values. It is commonplace for monitors to conclude adjustment at this step and release the resulting data as final. However, for ColorEdge monitors, EIZO additionally measures 25 points on the screen using a high- precision sensor different from the one used for the prior adjustment step. This achieves an environment closer to what users will experience. These measurement results are included in the report. EIZO only ships a ColorEdge unit after confirming that these points meet our strict standards for quality. This is how EIZO achieves highly stable display right out of the box. The above table lists the ⊿E00 and ⊿LR values for the 25 points indicated in the image preceding it. ⊿E00 and ⊿LR are defined as follows. |

- ⊿E00 (Delta E 00)

⊿E00 is a numerical value obtained by quantifying the human ability to perceive the difference in color between two points. The larger the value, the more visually distinct the colors appear to the human eye. Table 1 shows the color values for each point when the center point (point 13) is 0.00.

- ⊿LR (Delta LR)

⊿LR represents the uniformity of the screen’s brightness. Table 1 shows the brightness percentage of each point when the center brightness (point 13) is 100.00%.

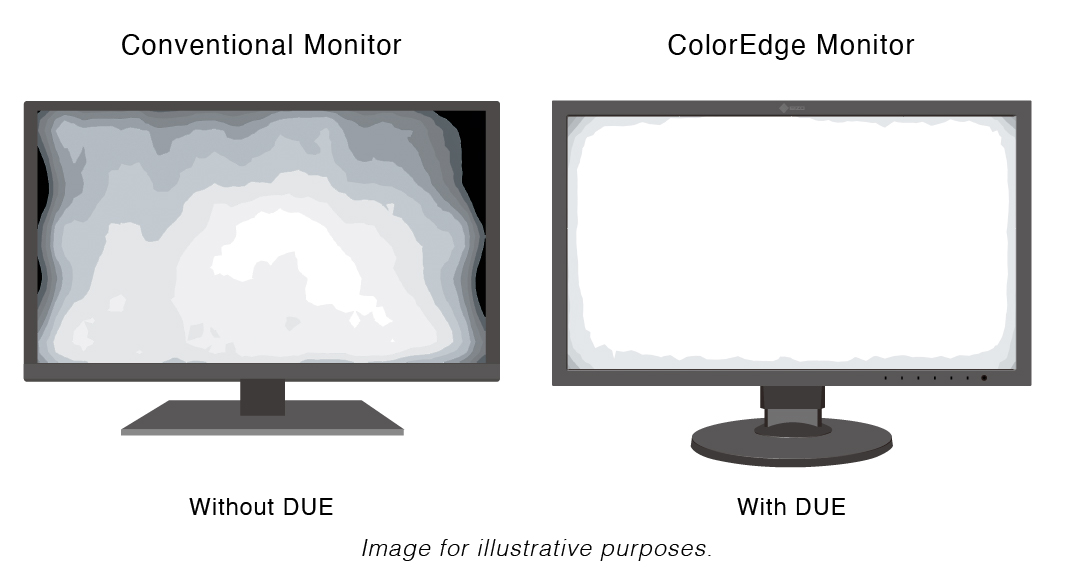

ColorEdge monitors are also equipped with EIZO’s patented Digital Uniformity Equalizer (DUE) which continues to correct fluctuations in brightness and chromaticity even after the monitor is installed in the user environment. This is achieved by controlling tonal values on a pixel-by-pixel basis.

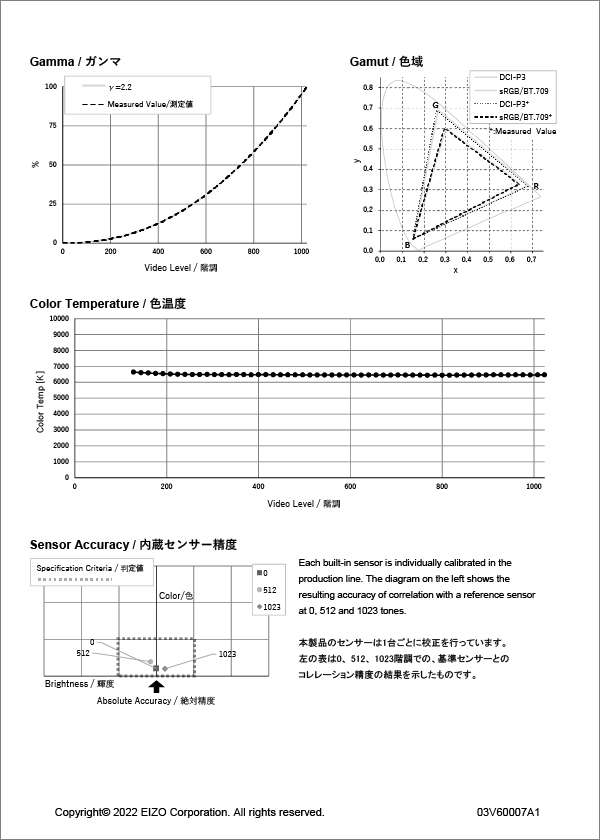

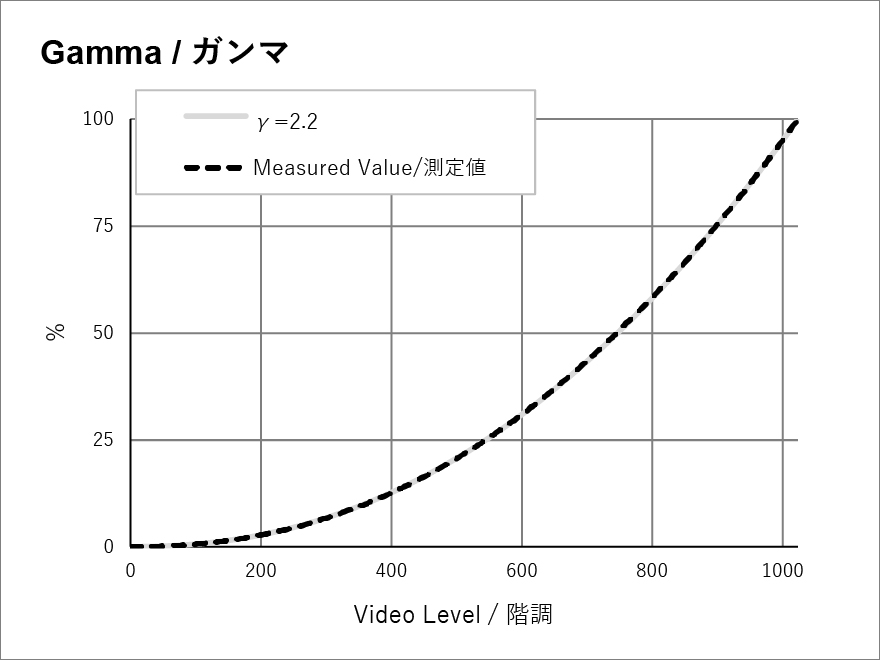

Gamma

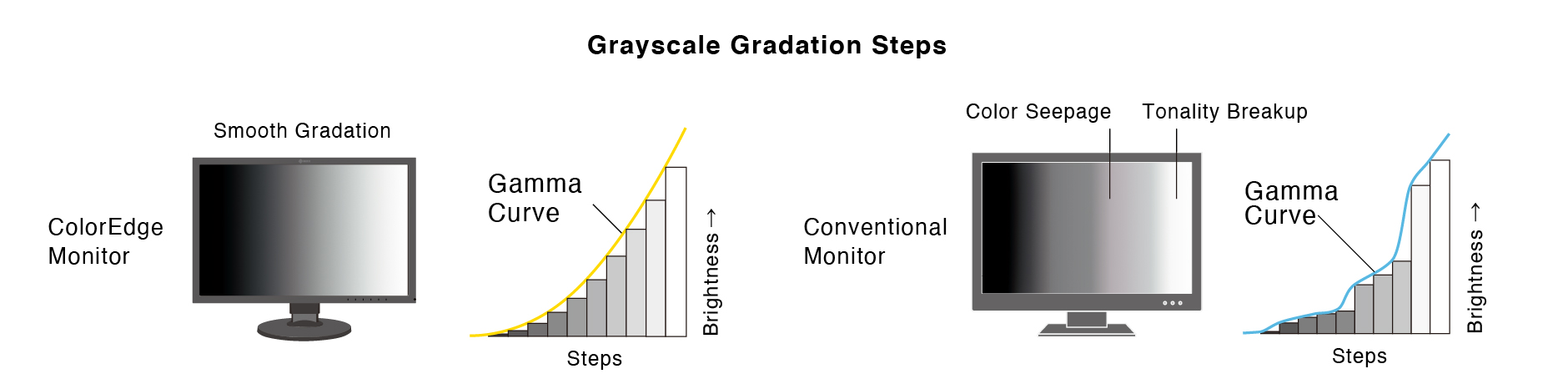

Gamma refers to the relationship between the numerical value of the signal being input to the monitor and the brightness of the screen (pixels). The brightness varies according to the input signal but is not always proportional to it. Gamma correction is the process of controlling the relationship between the input signal and brightness so that it remains constant.

Learn more about gamma

|

The standard gamma value for Windows or Mac is considered 2.2, so this is used as a reference for comparison. |

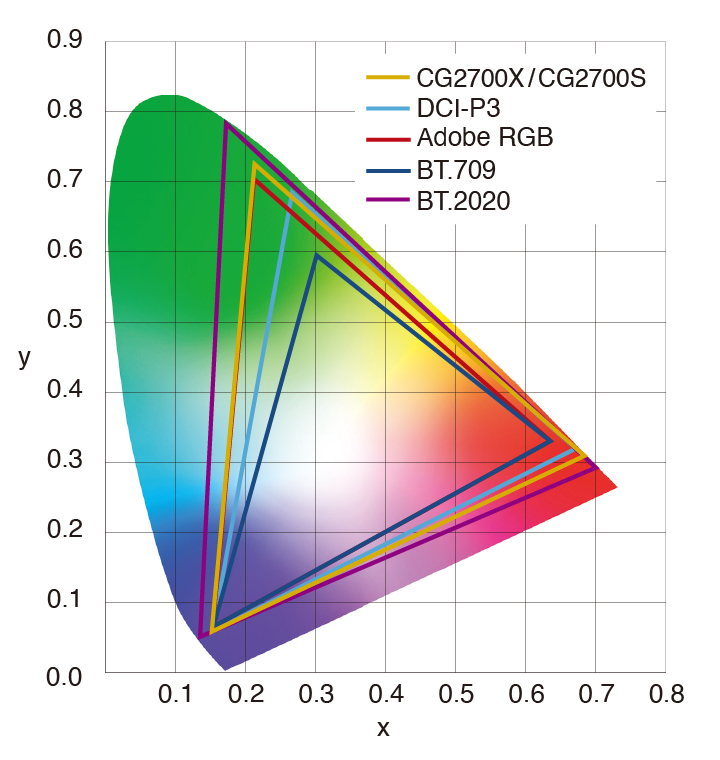

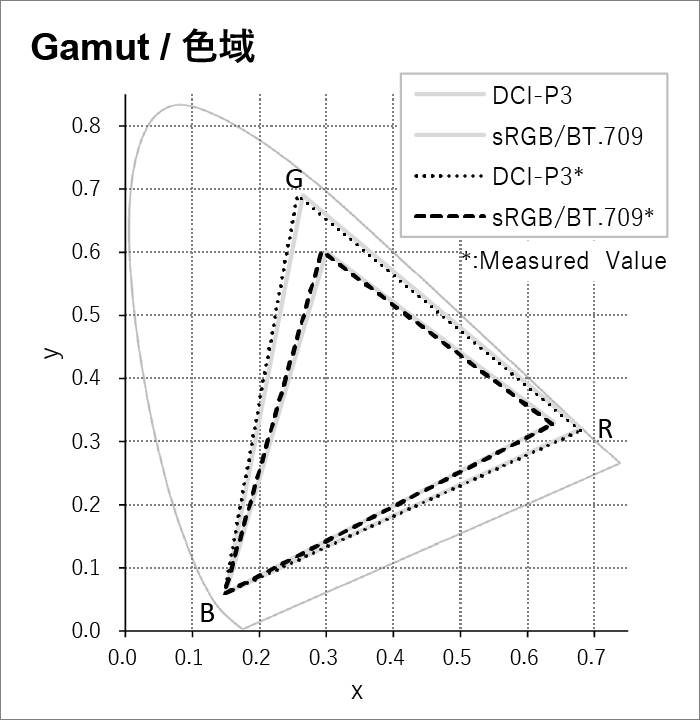

Gamut

Various standards govern color gamuts. A color gamut defined by a standard is depicted as a triangle on the xy chromaticity diagram established by the CIE (International Commission on Illumination). Most ColorEdge models are equipped with a wide color gamut.

Learn more about color gamuts

|

The Factory Report shows the RGB measurements of the adjusted ColorEdge compared to the sRGB/BT.709 and DCI-P3* standards. The color gamut defined by the standard is depicted with a solid line and the monitor’s measurement results with a dotted line. This shows how much of each color space standard the ColorEdge monitor covers.

*sRGB: A color gamut created by the IEC (International Electrotechnical Commission) to be used for monitors, printers, and the web. |

|

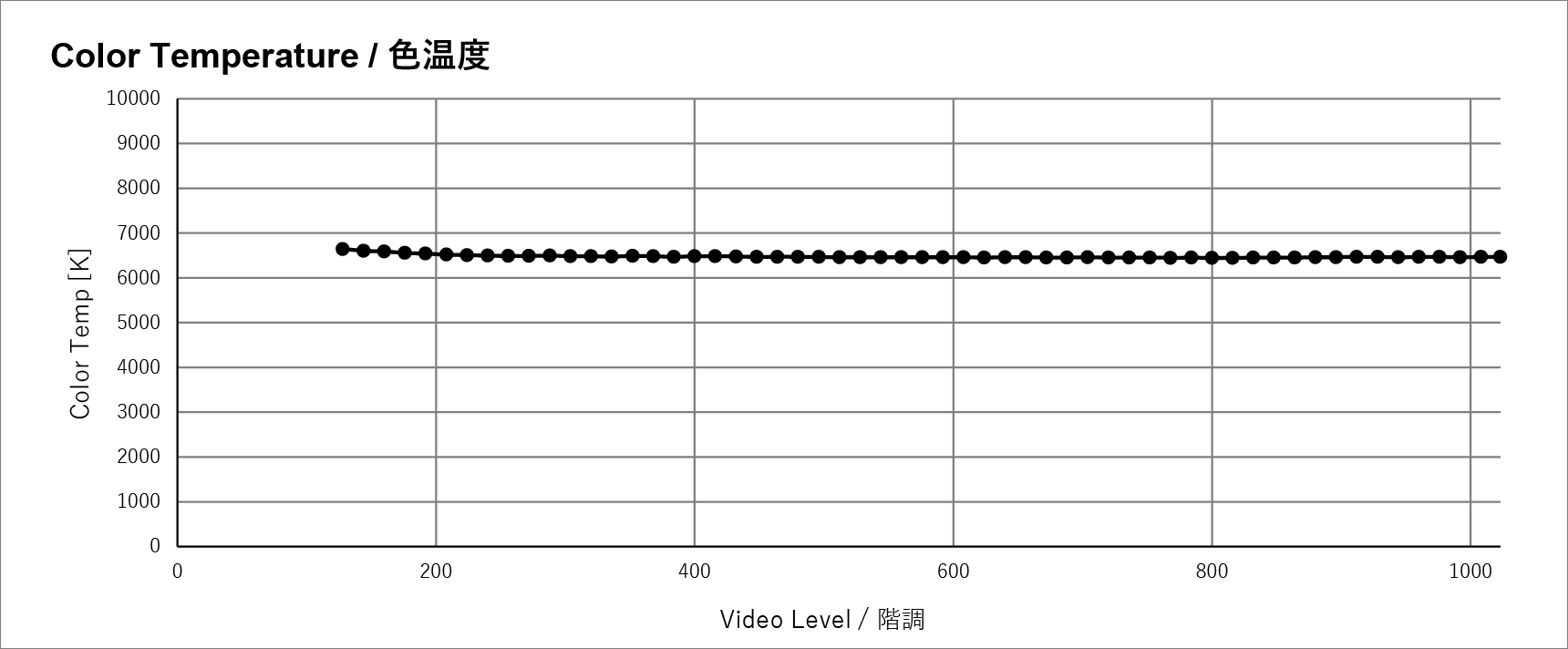

Color Temperature

Color temperature is usually used to express numerically the hue of white or black and is expressed in units of K (Kelvin). Not unlike the temperature of a flame, a monitor screen displays a reddish hue when the temperature is low and a bluish hue when it is high. In general, monitors veer on the side of higher color temperature so whites appear bluish in hue.

Learn more about color temperature

ColorEdge measures the color temperature of every tone at the factory. In the above graph in the Factory Report, if the line stays at 6500K, it means the monitor correctly reproduces white for each standard.

The color temperature of 6500K is the standard for general PC applications, the sRGB color space, and the international standard for digital high definition (ITU-R BT.709).

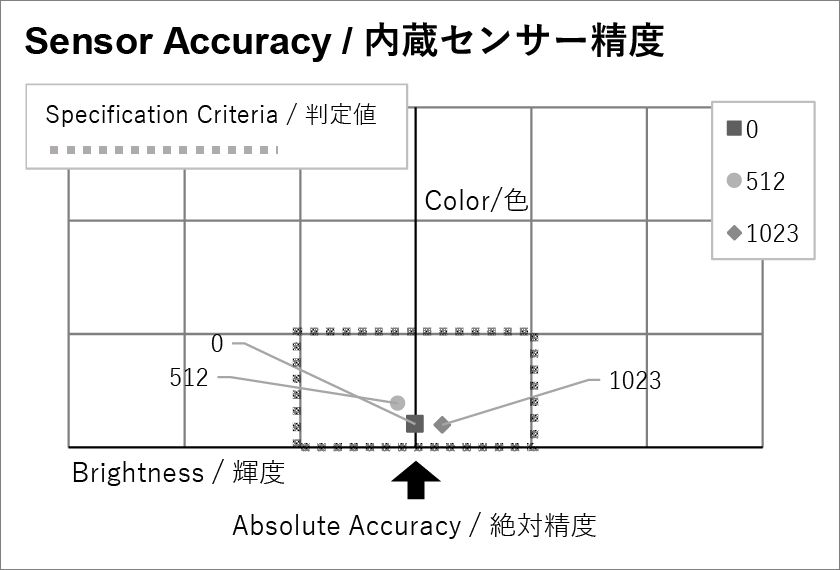

Sensor Accuracy

EIZO was the first manufacturer in the world to bring a self-calibrating color precision monitor solution to market in 2010. The proprietary built-in sensor equipped in ColorEdge CG Series monitors is developed and manufactured entirely in-house by EIZO. The absolute accuracy of the sensor’s brightness and chromaticity measurement capability is achieved by using one of the color industry’s higher-end, professional spectrophotometers as the standard to reference. In addition to built-in calibration sensors, every ColorEdge monitor is individually adjusted at the factory using the same reference spectrophotometer. This ensures ColorEdge is able to deliver precise color and brightness display with minimal deviation.

The Factory Report shows the results of correlation accuracy with the reference spectrophotometer for tones 0, 512, and 1023. The closer the result is to the center of the graph (indicated by the arrow in the above figure), the higher the absolute accuracy of the built-in calibration sensor. The area enclosed by the dotted line indicates the strict parameters within which the results must fall for EIZO to judge the values as accurate.

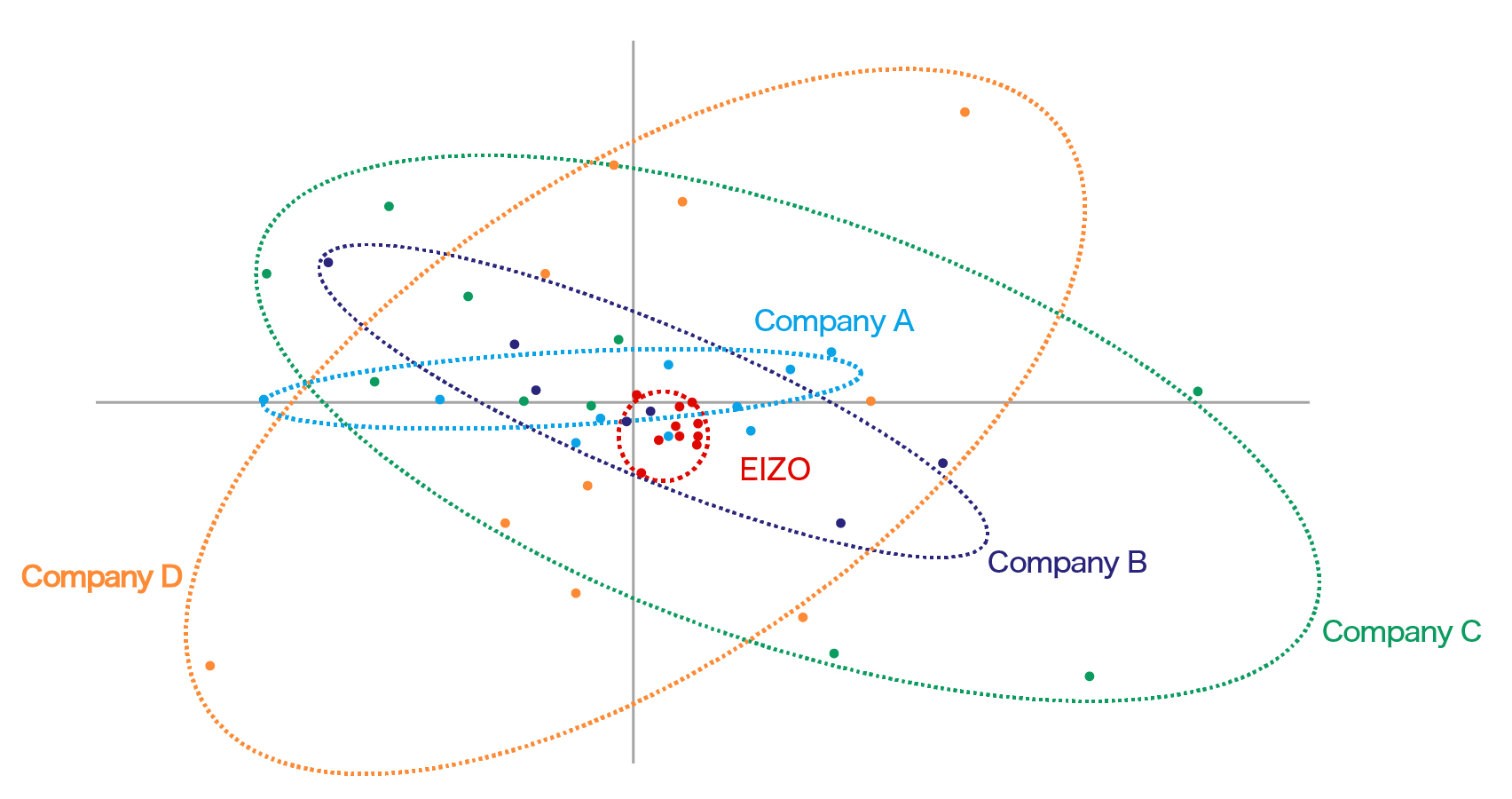

The below figure shows the resulting white point measurements of the ColorEdge built-in calibration sensor compared to external calibration sensors from other manufacturers. The figure shows that the ColorEdge (EIZO) sensor remains close to the center for each measurement point, indicating high accuracy of the white point, whereas other sensors deviate greatly by comparison.

CS Series monitors are not equipped with a built-in sensor.

Learn more about the ColorEdge built-in calibration sensor

Rest Assured with ColorEdge

ColorEdge monitors are carefully measured and adjusted one by one before being shipped out from the factory. EIZO publishes the results in a comprehensive report to provide customers peace of mind to use their ColorEdge monitor with confidence. The information provided can be summarized as conveying two major benefits:

- ColorEdge monitors undergo rigorous quality during production and are adjusted at the factory using one of the industry’s higher-end calibration spectrophotometers as the standard to ensure optimal image quality.

- The built-in calibration sensor for CG Series monitors achieves highly precise and convenient color management.

In addition, with EIZO’s ColorNavigator color management software, users can create and edit adjustment targets, schedule automatic recalibration, and manage multiple monitors without any hassle. This ensures every screen maintains high precision over time and minimizes the time and costs needed for color management related tasks so users can focus on creating with peace of mind.

Uniformity refers to how consistently color and brightness appears across the monitor’s screen. Before adjustment takes place, LCD monitors characteristically have an unavoidable “unevenness” across the screen which affects the accuracy of color reproduction. To counteract this, EIZO performs 2D measurement and adjustment for all shades of gray across the screen for every ColorEdge monitor at the factory. This ensures stable display with minimal deviation.

Uniformity refers to how consistently color and brightness appears across the monitor’s screen. Before adjustment takes place, LCD monitors characteristically have an unavoidable “unevenness” across the screen which affects the accuracy of color reproduction. To counteract this, EIZO performs 2D measurement and adjustment for all shades of gray across the screen for every ColorEdge monitor at the factory. This ensures stable display with minimal deviation. A sensor is placed directly over the monitor and red (R), green (G), and blue (B) gamma values for all tones from 0 – 255 (for 8-bit) and 0 – 1023 (for 10-bit). This is done for every ColorEdge before leaving the factory. The above graph shows the measurement results of the gamma for every tone. If the values are aligned with the gamma 2.2 curve, it means that the ColorEdge monitor has achieved the ideal gamma curve for accurate grayscale reproduction without deviated steps.

A sensor is placed directly over the monitor and red (R), green (G), and blue (B) gamma values for all tones from 0 – 255 (for 8-bit) and 0 – 1023 (for 10-bit). This is done for every ColorEdge before leaving the factory. The above graph shows the measurement results of the gamma for every tone. If the values are aligned with the gamma 2.2 curve, it means that the ColorEdge monitor has achieved the ideal gamma curve for accurate grayscale reproduction without deviated steps.