Sustainability

New Value

EIZO, as a Visual Technology Company, will create total imaging solutions that address the social issues and enrich people in their professional and personal lives.

Creating Value for Key Markets

Business & Plus (B&P)Healthcare

Creative Work

Vertical & Specific (V&S)

Our Integrated Approach

DevelopmentManufacturing

Quality Assurance

Business & Plus (B&P)

Choose EIZO, Work Better

The FlexScan series offers excellent image quality and reliability as standard performance features. It also includes advanced features and functions resulting from years of dedicated work in environmental performance and ergonomics, such as minimizing eye fatigue.

EIZO products achieve the most advanced environmental performance in the industry, including an energy-saving design that contributes to reducing CO2 emissions and improved recyclability. They have also been designed so users can work comfortably for extended periods and offer a virtually frameless design for a seamless view across multi-monitor configurations and reduced screen brightness and reflection. Moreover, we have a variety of models that incorporate USB Type-C for compatibility with notebook PCs to contribute to user productivity in the office and while teleworking.

EIZO products are friendly to the environment and ergonomically sound, and widely used within financial trading institutions as well as in offices and educational facilities.

- Comfortable stress-free trading with frameless multiple monitors

- Increase office productivity by connecting the monitor with a notebook computer

- Multiple monitor configurations aid CAD operations

-

Streamlined connection with USB Type-C

Healthcare

Making Each Life Visual

The importance of medical imaging is growing in our current healthcare service along with advanced medical devices.

In case of team medical care for surgery, doctors and other medical staff need to simultaneously share the patient’s information and a huge amount of numerical data, images, and videos. Also, the surgery videos may also be used for research and education as well as records of the medical treatment.

To achieve this kind of effective imaging operation, EIZO provides consulting services to propose comprehensive visual solutions and soundly address user needs that encompass image display equipment, peripheral equipment, software, and network layout, enabling the construction of an optimal visual environment. By taking full responsibility for the entire process from capturing, recording, distributing and displaying, we are able to revolutionize the video

environment in hospitals, including operating rooms.

- Diagnosis

- Examination

-

Treatment

See case studies about Healthcare

Creative Work

Pure Vision. True Precision.

Our ColorEdge series, which we were committed to the color reproduction quality, increases accuracy and work efficiency in creative settings including photo editing, design, printing and video production by achieving and maintaining accurate color display.

Built-in calibration sensors and EIZO’s own color management software enable users to adjust their monitor settings to their individual needs. Also, its own color management solution enables users to simultaneously set the color mode for multiple ColorEdge monitors over a network. This, in turn, enables them to maintain uniform color display throughout the entire workflow, from production to referencing, even when finishing a product with remote work environments, including video production at multiple sites, which boosts the work efficiency of the monitor administrator.

- Hobby Photography

- Pro Photography

- Illustration

- Design

- Printing

-

Post Production

See case studies about Creative Work

Vertical & Specific (V&S)

Durability × Quality × Everywhere

EIZO provides visual environment solutions used in specialized applications and environments in areas such as air traffic control, maritime, security and surveillance, railway and factory automation.

We serve diverse needs ranging from improving visibility to ensuring high reliability and display performance that can withstand harsh operating environments. We meet each and every requirement including small quantity production, flexible customization, stable long-term supply, and reliable long-term maintenance by harnessing the visual technology and know-how we have accumulated over the years.

- Air Traffic Control

- Maritime

- Security & Surveillance

- Railway

-

Factory Automation

Development

The EIZO Group will continue creating the world’s best products. We have established a fully integrated in-house system for product planning, development, manufacturing, quality control and aftersales service. This has enabled us to accumulate a wealth of visual technologies and expertise within our organization.

Accumulating Unrivaled Visual Technologies

We have accumulated a wide variety of visual processing technologies by meeting the high requirements of specific markets such as healthcare, creative work, and Vertical & Specific (V&S) based on developments incorporated in monitors for the Business & Plus (B&P) market.

In particular, the unrivaled quality and reliability essential for these specific markets are realized in both hardware and software technologies. The impressively high image quality and performance associated with our advanced hardware technology is thoroughly managed by a variety of software technologies. The solutions created in this way have been successfully deployed for professional applications that require a consistently high degree of accuracy over long periods of use.

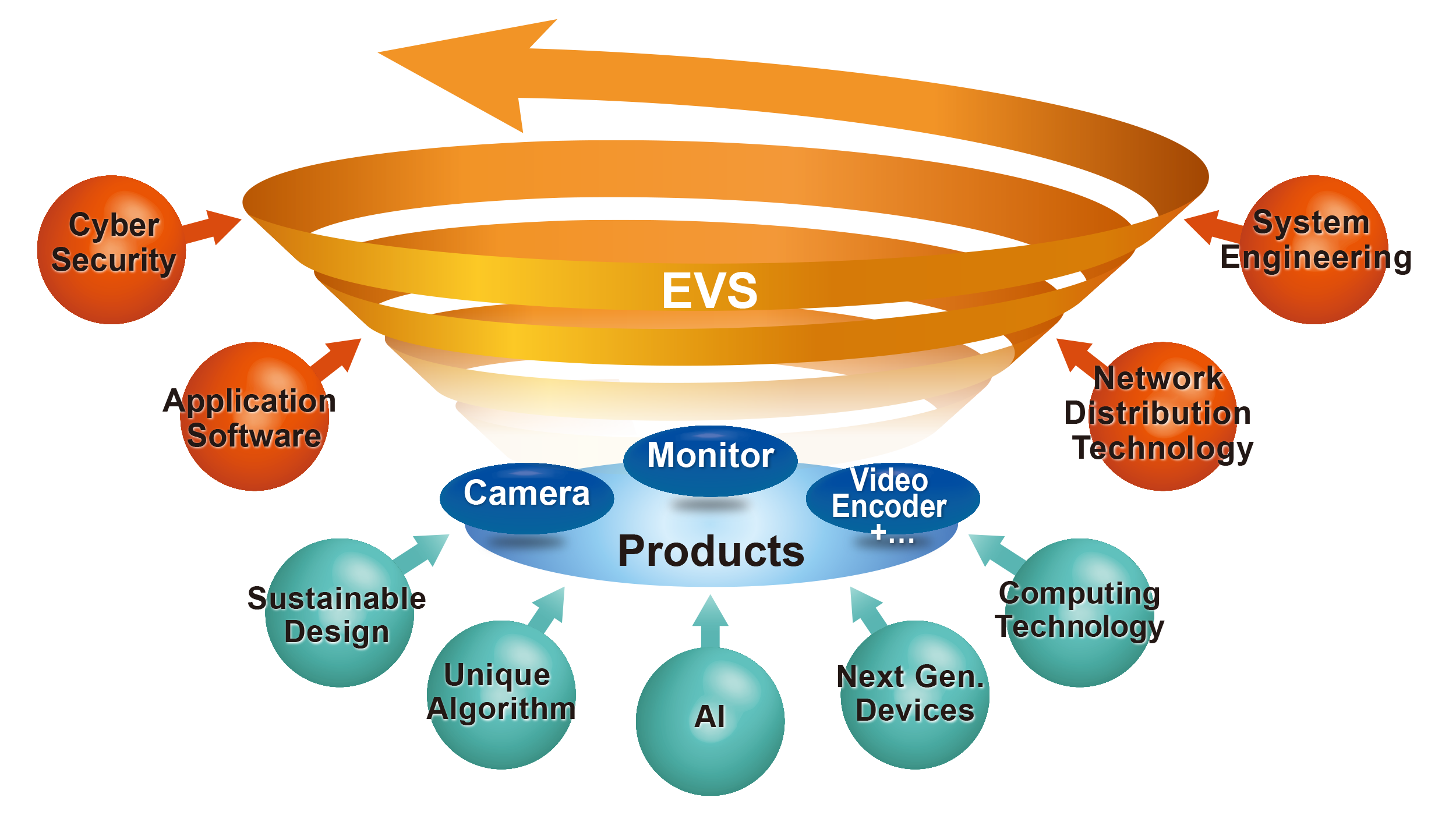

New Technologies to Amplify Imaging Value

We are focusing on developing the technologies necessary to amplify imaging value, from viewing to actual application. Specifically, we are striving to dramatically improve performance through the integration of our proprietary algorithms and AI technology, develop computing technologies for implementing these algorithms in cuttingedge GPUs to achieve the ideal processing for each application and develop various video codecs to robustly transmit visual information in mission-critical markets, as well as develop environmentally sound technologies that help contribute to sustainability. We also implement these technologies to drive the evolution of monitors, cameras, video encoders, and other products, and we are upgrading network transmission technologies, application software, and system engineering to connect all these products in one effective system. We form an imaging chain from the initial input to output of visual data, including image capturing, recording, distributing, and displaying to evolve our EVS business. With the accelerating influence of DX, the role of imaging technology is becoming increasingly important. We will evolve our system solutions to be comprehensive and have additional value to support users in their efforts to automate and streamline their operations and improve the accuracy.

Devices Creating Products Committed to Exceeding Expectations

Novel devices and image processing technologies are vital for creating innovative products. We therefore pay close attention to the performance of key display devices in strong partnerships with each device manufacturer. In addition, we develop and produce specialized display devices inhouse through our unique technology development and manufacturing methods or apply special processing to display devices as needed, for example, to meet special applications or super-reliability requirements.

Moreover, we have developed our proprietary control systems (firmware) that maximize the ability of display devices to even surpass necessary performance levels, as well as our very own ASIC and FPGA image processors.

The Spirit of Global Development

EIZO maintains R&D and manufacturing facilities in multiple locations globally. Each year, EIZO Group companies responsible for R&D gather at the headquarters to introduce their technologies at the in-house exhibition ‘EIZO Technology Showcase’ in order to continue to create the world’s best. This is an important opportunity not only for engineers to exchange information but also for sharing EIZO’s future strategy and vision with sales, planning and manufacturing staff from around the globe.

We also hold global meetings by market to share detailed information on needs and technologies.

Note: Due to risks surrounding COVID-19 we canceled the ‘EIZO Technology Showcase’ for fiscal year 2020. Global strategy meetings for each business unit were held online.

Manufacturing

“Stop looking for the reasons why you cannot do it. Think seriously how you can do it!!”

This statement originates from an EIZO production site and is now widely shared as the philosophy of EIZO’s manufacturing. Each and every employee embodies this philosophy, taking pride in their work.

Integrated Group Production as EIZO’s Proven Strengths

Our monitors are manufactured within the group in an integrated manner, from manufacturing of electronic circuit boards to assembly and inspection of finished products. Close alignment among all the teams and their united pursuit of ever-improved manufacturing have allowed EIZO to create products that reflect the world’s first-class quality and reliability.

More than 90% of circuit boards mounted on EIZO’s monitors are manufactured at the Hakui Factory of EIZO MS Corporation in Ishikawa Prefecture and supplied to the assembly factories of the EIZO Group in Japan (Ishikawa Prefecture), China, and Germany.

At each factory, our R&D and manufacturing departments work together from the development stage, freely exchanging ideas for improving manufacturing operations. In addition, our Information Systems Department joins to analyze the massive volume of quality data accumulated daily in the production process. This is to ensure the data is fully used to constantly improve the development of new products, production systems, and process design. Moreover, our agile and stable procurement function optimizes the manufacturing process regardless of ever-changing market demand and material availability.

The EIZO Group’s manufacturing strengths and competitive power are built on a strong sense of unity across departments and countries.

The Spirit of Manufacturing and Technologies

We have consistently incorporated state-of-the-art technologies into EIZO products, which requires the continual refining of our manufacturing expertise and skills. Thus, we provide regular training to all workers at our production sites to continually improve their skills. We also organize annual factory tours for employees of our group companies to share EIZO’s manufacturing spirit and technologies globally.

Note: Due to risks surrounding COVID-19, factory tours were not conducted in fiscal year 2020.

Manufacturing Circuit Boards Meeting High Quality Standards

|

To maintain high quality standards in the mounting of electronic components, the latest equipment is used to adjust the mounting position at micron levels. X-ray inspection prevents defective components from leaving the line by checking areas that cannot be inspected visually, and automated optical inspection confirms the mounting status of all components. The EIZO logo is firmly printed on all circuit boards made to prove the high reliability of EIZO monitors. |

|

Advanced Production Facilities Using AI, Robotics, and IoT

Approximately 80% of the EIZO monitors worldwide are produced at the factory in Japan. Here, monitors are mass produced on four production floors, each with its own characteristics, as shown in the table below, using the optimal production method according to product characteristics, required production volumes and delivery date requirements.

The hybrid floor has a state-of-the-art production line that promotes labor saving and automation by taking advantage of AI, IoT, and robotics. This production system collects data in real time such as production progress, the operating status of equipment and measuring instruments, and the state of product adjustment. Analyzing this big data supports continual improvements in product quality and processes. In addition, we promote the digitization of onsite records using tablets at production sites. We are striving to further improve productivity by accelerating data analysis.

| Production Floor | Products Produced |

|---|---|

| Belt conveyor floor | Products for business applications with high production volume per model (mainly B&P) |

| Cell floor | Various products in small lots for specific markets (mainly V&S), each product requiring different adjustments and inspections |

| Hybrid floor | Products that are difficult to adjust and therefore time-intensive because of the many adjustment and inspection items (mainly healthcare and creative work); two-thirds of the entire process can be fully automated |

| Master floor | Products with our uniquely customized panels (mainly V&S); includes a large clean room and special equipment |

Inspection System for Catching the Smallest Abnormality

|

For every single unit we perform a thorough inspection, both visually and mechanically. After going through automated inspection processes, such as screen uniformity, the final image quality inspection is conducted visually by inspectors who have been certified in-house. Monitors are products that people constantly stare at, so we believe in the importance of inspection using the human eye. |

|

Quality Assurance

We never compromise on quality and always strive to deliver highquality products, systems and services that enhance the convenience and increase the value of our customers’ visual environments.

EIZO Group Quality Basic Policy

Last revised on Apr.25, 2012

The EIZO Group is committed to continually fulfilling customers' expectations by proposing and offering high quality products, services, and solutions.

We therefore:

- Aim to develop high quality products by pursuing the world's highest level of technology.

- Carry out our responsibility for environmental preservation by actively reducing the effects on the environment in every business activity from product development to manufacturing to sales and service.

- Set the quality target which are carried out and reviewed by all the employees in every business activity.

- Establish a quality management system, review it periodically, and continually improve it to sustain its validity and suitability.

- Meet the expectations of both healthcare professionals and those who receive medical treatment by providing medical devices with assured quality, effectiveness, and safety.

- Comply with legal and social requirements.

Mr. Kenichi Fujii

Executive Operating Officer

Research and Development

Certifications

These certifications have been maintained and updated by third parties through external audits.

ISO9001 (Quality Management System)

| Standard | ISO 9001:2015 | |

|---|---|---|

| Certificate Registr. No. | 09 100 3295 | |

| First Certification | 1993 | |

| Scope | Product planning, design/development, manufacturing, sales and service of display monitor equipment and peripherals used for computers, entertainment and computing systems | |

| Certification Body | TÜV Rheinland Cert GmbH | |

ISO13485 (Medical devices Quality management system)

| Standard | EN ISO 13485:2016 | |

|---|---|---|

| Certificate Registr. No. | SX 601461700001 | |

| First Certification | 2005 | |

| Scope | Design and Development, Manufacture, Distribution, Installation and Service of Display monitor equipment and Peripherals for Medical systems (OR, IVR, Diagnostic imaging system and PACS) | |

| Certification Body | TÜV Rheinland LGA Products GmbH | |

Ensuring Quality in Planning & Development—Strengths of In-house Development

At the planning and development stages, by taking advantage of the concentration of departments related to manufacturing, such as planning, development, and production, we have achieved superior standards of quality through application of the Group’s fully integrated in-house development system. In addition to complying with the laws, regulations and standards of each country, we are rigorously assessing risks for each market and application to conduct verification, based on our own reliability standards that reflect diverse events and cases.

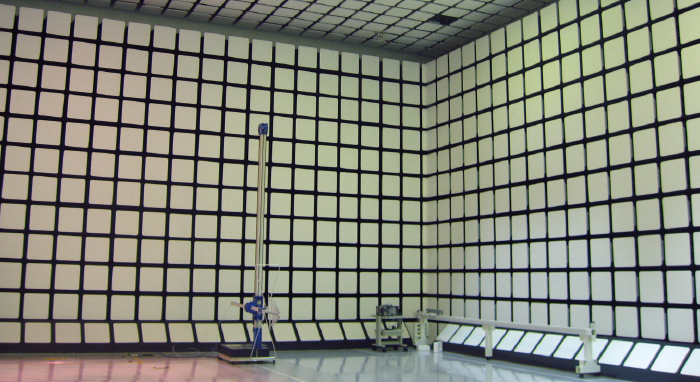

We also have our own in-house testing equipment for EMI, EMS and other safety standards, including reliability tests such as high and low temperature tests as well as vibration and drop tests. EIZO’s prompt and careful quality tests in accordance with international standards as well as smoothly delivered feedback to the design and manufacturing teams play major roles in continuously maintaining and improving quality.

Main Testing Equipment

MIL-STD-810 Environmental Testing and AssessmentEIZO in-house testing equipment and facilities are capable of conducting tests under harsh conditions such as extreme temperatures and humidity, vibration and shock in accordance with the standards and assessment guidelines for materials procured by the U.S. Department of Defense. Passing the evaluation proves products are able to operate safely in extreme environments.

|

Anechoic Chamber

We obtained EMC testing facility certification in 2002 from the U.S. National Voluntary Laboratory Accreditation Program of the U.S. National Institute of Standards and Technology (NIST), based on ISO/IEC 17025 requirements. We also obtained certification from TÜV in 2003.

|

Ensuring Quality in Procurement

|

EIZO procures more than 10,000 parts from around the world. To provide stable products, systems and services, it is essential to source only quality components. In addition to establishing procurement policies and guidelines and providing them to suppliers, we achieve our quality goals by collaborating with suppliers to ensure quality through the evaluation and verification of samples during the development stage.

|

|

Ensuring Quality in Production

At each stage of production, important key parameters such as brightness and contrast are automatically recorded and saved and analyzed from various perspectives for real-time quality monitoring. We use this big data to quantify quality control standards, improve production efficiency and provide feedback for new product development.

Ensuring Quality in Sales and After-Sales Service

EIZO conducts sales and after-sales activities through our 17 group companies and 20 authorized distributors (as of August 2021).

Working closely with our group companies and authorized distributors through our global network, we are constantly sharing the latest information. In each territory we provide prompt and solid support as well as reliable after-sales service to users by playing a role in monitoring and collecting market quality information and providing feedback on customer needs.

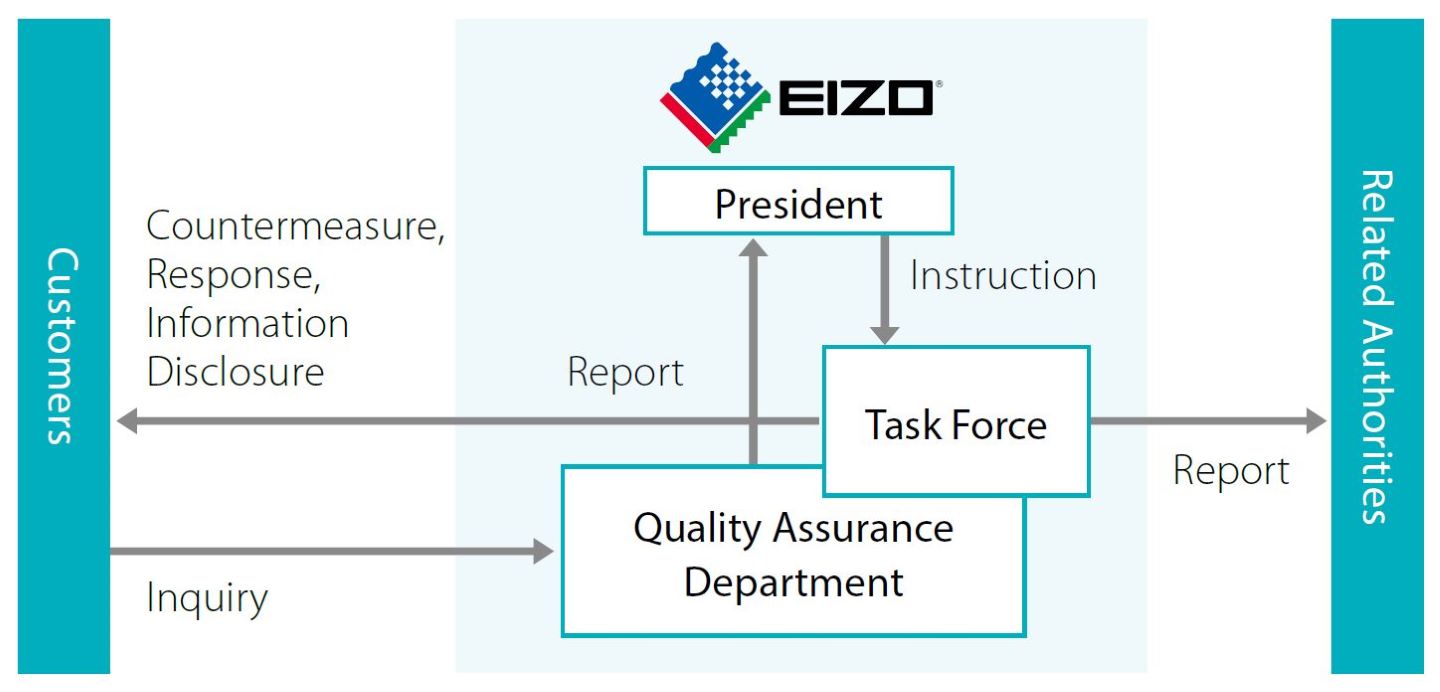

We focus on preventing quality-related incidents. In the unlikely event of an issue related to safety or quality, we will take prompt and appropriate measures (e.g., cause investigation, countermeasure implementation, product repairing, information disclosure, etc.).